One of the most powerful workhorses of the industry is also one of the simplest types of technologies inside factories and plants: AODD pumps.

One of the most powerful workhorses of the industry is also one of the simplest types of technologies inside factories and plants: AODD pumps.

Air-operated double-diaphragm (AODD) pumps can handle the harshest fluids in the toughest environments. With just a handful of parts, AODD pumps remain reliable, while requiring little maintenance. They're also versatile, and well-suited for a broad range of industries—from mining to food and beverage production.

How does such a simple piece of machinery keep production moving at top speed? The answer is in the pump components.

How Each Component of Diaphragm Pumps Are Important to Its Operation

By understanding AODD pump basics, you can make choices that help your AODD pump perform at its best in a specific application.

These are the basic parts and components of an AODD pump:

.png?width=575&name=AODD_Pump_Components_Graphic-2%20(1).png)

Read on to find out more about each specific pump component.

Fluid Side Components

The Fluid Suction/Discharge Manifold

- It's bolted or clamped to the outer chambers to create a seal and a flow path for the fluid to follow.

- Valve/seat seals make a leak-free seal between the manifolds and the outer fluid chamber, as well as house the valve balls in the ball cages within the manifolds.

The Outer Fluid Chamber

- It's part of the fluid path within the pump.

- It's attached and sealed at the suction and discharge manifolds by the seats and/or seat seals. It's also sealed between the inner chamber/air chamber with the bead of the diaphragm.

- It creates a void where the reciprocating diaphragms draw fluid in and then push it out on each side to create the pumping action.

The Diaphragms

- They act as the barrier that separates the fluid side of the pump from the air side.

- The diaphragms (in standard designs) maintain a seal at two points:

- 1) At the center diaphragm hole by tightening the inner and outer diaphragm plates to the main shaft, capturing the diaphragm. When properly torqued, a leak-free seal is created.

- 2) A seal also occurs at the outer circumference of the diaphragms, usually at the molded-in sealing bead or from sealing grooves on the inner air chamber and/or outer fluid chamber. The seal occurs from the compression created when the outer chamber bolts (bolted pumps) or the large clamp band assemblies (clamp style pumps) are tightened.

- Some bonded PTFE diaphragm designs incorporate (over-mold) the inner and outer diaphragm plates so no center hole is present. These bonded diaphragms do not require separate diaphragm plates and can simply be hand tightened onto the threaded diaphragm shaft. This design is a preferred choice for many hazardous chemical applications.

- The diaphragms are dynamic components that are actuated (flexed) when air pressure is delivered behind the diaphragm on the aid side of the pump. The modulated air pressure exerts force on the air side of the diaphragms, which in turn exerts that equal force to the fluid being pumped.

- Diaphragms come in a variety of materials and designs to meet specific application needs such as chemical compatibility, temperature, abrasion resistance, and certification requirements. Consult the manufacturer for further details.

The Inner/Outer Diaphragm Plates

- These work in conjunction with the diaphragms to separate the fluid side of the pump from the air side.

- The plates are threaded to the main shaft/diaphragm rod, compressing the diaphragms and creating an air-tight and fluid-tight seal.

- The diaphragm plates also support the diaphragms as the shaft is reciprocated, causing them to create a vacuum on the fluid, drawing the liquid into the pump’s fluid chambers and then pushing it out.

Clamp Assemblies or Bolts

- They're used to assemble the pump components; pumps come in either clamped style or bolted construction.

- In conjunction with the diaphragms and valve seats, these create a seal that keeps the fluid in the pump and separates the air side from the fluid side.

Air Side Components

The Main Shaft/Diaphragm Connecting Rod

- It connects the diaphragm assemblies (inner/outer plates and diaphragms).

- Shafts can be male or female-threaded and connect to the outer plates via those threads.

The Inner Chamber/Air Chamber

- It holds a seal with the diaphragms when compressed air is introduced into each side in an alternating manner. This exerts pressure on the backside of the diaphragms that, in turn, exerts pressure on the fluid.

The Air Valve

- It directs compressed air into one of the two air chambers in order to shift the diaphragm/connecting rod assembly. At the same time, the air valve is porting air from the opposite air chamber, allowing it to be exhausted to the atmosphere via the intermediate/center block exhaust port.

The Intermediate/Center Block

- It usually guides the main shaft/diaphragm rod with seals and bushings. The main shaft, or the pilot shaft (depending on the manufacturer’s design), delivers alternating pressure to the air valve to shift the main valve spool—this causes the pump to reciprocate and create the pumping action. Air is also, in most cases, exhausted from the intermediate block via the exhaust port and out of the air exhaust muffler.

Air Exhaust Muffler

- It helps to reduce the sound of the exhausting air from the pump; various types, materials and sizes are available. The muffler can also be removed so the exhaust can be ported away from the pump, enabling the pump to be submerged, or to simply exhaust the air to a safe location or outside to further reduce noise in the work environment.

How AODD Pumps Operate

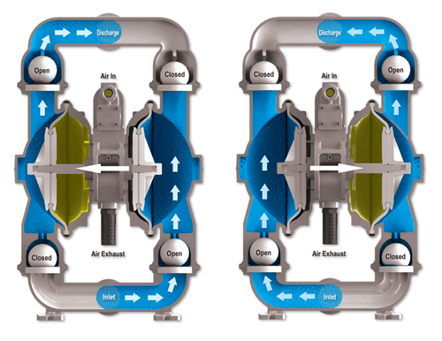

Now that you know about the basic components of an AODD pump, let’s explore how they operate. Below is an example of a cutaway AODD unit that shows how the main pump components work.

The Suction Cycle

Compressed air fills the left inner chamber, causing the opposing diaphragm to create suction, lifting the lower valve ball to pull in fluid at the inlet. Simultaneously, the left fluid chamber is in the “discharge” cycle.

The Discharge Cycle

Compressed air fills the right inner chamber, causing the upper valve ball to open and discharge fluid. Simultaneously, the left chamber is in the “suction” cycle.

Important Pump Component Considerations

When selecting a pump for a specific application, certain pump components can make a big difference in overall performance and meantime between failure (MTBF).

The Valve Balls

Tip: Heavy/weighted valve balls should be used when pumping thick, viscous liquids.

A heavy valve ball will cut through the thick product and seat faster when pumping thick liquid due to gravity. This will allow the pump to be more effective when pumping thick fluids. PTFE or stainless-steel valve balls, for example, are much heavier than valve balls made of Santoprene or other materials.

The Valve Seats

Tip: Choose abrasion-resistant valve seats.

When pumping abrasive fluids, consider using valve seats made from an abrasion-resistant material. For example, if pumping abrasive ceramic slip, replace rubber valve seats with stainless steel to reduce the wear associated with abrasive applications. For plastic pumps, PVDF is more abrasion resistant as compared to polypropylene.

The Air Side Materials (air valve, center section / non-wetted side of the pump)

Tip: For the air side of the pump, select a material that is chemically compatible with the fluid being pumped.

The fluid being pumped does not just contact the wetted side of the pump in most cases. The fluid is certain to encounter the air side of the unit as well, either by the environment around the pump or when a diaphragm fails. The surrounding environment can have fumes or the pump can get splashed with chemicals from the process. If that is the case, then you need to make sure the air side (air valve, center block, air chambers, etc.) is also comprised of chemically compatible materials of construction.

This is also true when a diaphragm failure occurs. When a diaphragm fails, the liquid can contact the air side of the pump, and can cause damage if the materials on the air side are not compatible with the fluid being pumped.

Using a material that is chemically compatible on both the air and wetted side will extend the life and performance of the pump and, in most cases, will be worth the additional upfront cost associated with some air side materials (such as stainless steel). Polypropylene and coated metal air side components are also good options to consider.

Selecting an AODD Pump

AODD pumps can handle a wide range of chemicals, flow rates and viscosities, and can perform well in a broad array of industries.

Though diaphragm pumps are very simple to understand, the more you know about some of their specific components, the easier it will be to find the best pump for your application.

When it comes to choosing a pumping partner, the decision is easy. For almost 40 years, Versamatic has been manufacturing AODD pumps to meet the challenges of industries across the world.

Whether you’re seeking a new pump or need replacement parts and accessories, you can count on Versamatic’s proven products and expertise.

Learn how the reliability and durability of Versamatic pumps serve a wide range industries in our most recent case study.

Find these tips useful? Share which tip helped you the most in the comments below.

.png?width=272&height=66&name=headLogo%20(1).png)

.png?width=300&height=71&name=Versamatic_white-logo%20(1).png)