If you have ever ordered, specified, repaired, or supported an industrial pump, you have probably faced a familiar moment: you are looking at a model number and trying to confirm exactly what it represents. Is it the same pump you used last year? Is it the right material set for the fluid? Does it meet your site requirements? Does it include the safety rating you need?

For many people, model numbers can feel like a random string of letters and numbers. In reality, a good model number is one of the most efficient communication tools in industrial equipment. That is the purpose of nomenclature.

Versamatic has used nomenclature for years to help identify pump construction and major components. As pump designs have evolved and configuration options have expanded, Versamatic has updated its nomenclature system to provide a higher level of detail directly within the model number. The result is a more direct way to identify what a pump is built to do and what options it includes.

What Is Pump Nomenclature?

Nomenclature refers to a standardized system or set of rules used for naming things within a product line. In industrial equipment, nomenclature often takes the form of model numbers.

A nomenclature system is built to ensure that everyone can communicate clearly and accurately without confusion. It is especially important in technical disciplines where products may look similar on the outside, but differ significantly in construction, performance, or compatibility.

In short, nomenclature gives complex products a universal, unique name.

Why Use Nomenclature and What Are the Key Benefits?

Nomenclature is not about making product names complicated. It is about making them precise. When a naming system is well designed, it helps everyone involved in selection, purchasing, maintenance, and support.

Universality

One of the most valuable aspects of nomenclature is that it works across borders. Common names vary by region, industry, and even by individual plant. Model numbers do not.

A standardized model number can be recognized globally, regardless of local language or regional naming habits. This matters when pumps are specified by engineers in one country, ordered through distribution in another, and installed at a facility somewhere else.

Precision

Nomenclature eliminates ambiguity. Common names can be vague and may refer to multiple products that are not actually the same.

For example, a common name like “Versamatic 2” flap pump” can refer to multiple configurations, including different body materials, diaphragm materials, air valve constructions, and compliance options such as ATEX. While the description may be commonly used in conversation, it is not specific enough to identify the exact build or performance characteristics of a particular pump.

A model number, by contrast, is designed to point to one exact pump and build. That precision helps reduce mistakes in quoting, ordering, and installation.

Organization

Model numbers also provide structure. In many product lines, nomenclature reflects how pumps are classified and how they relate to one another.

A shared platform name often indicates close design relationships. That can help engineers and maintenance teams understand which pumps have similar parts, performance ranges, or internal architecture.

For manufacturers, this organization is also useful when releasing new models or expanding options within an existing line. A consistent naming system makes it easier to add new configurations without confusing the market.

How Versamatic Nomenclature Has Evolved

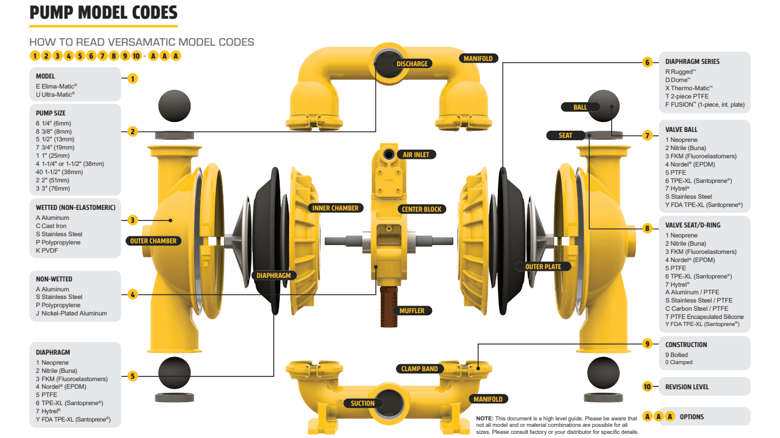

Versamatic has long used nomenclature as a way to identify the basics of pump construction. Our E-Series nomenclature was used for many years and served an important role in product identification.

The E-Series System

The E-Series nomenclature was designed to identify the core construction of the pump. In many cases, it allowed users to recognize major components and sometimes the application.

Additional specifications could be included by adding characters to the end of the model number. These add-ons varied in length and were used to call out specific requirements.

Examples include:

- FP

- -F

- -B-ATEX

For the time and product options available then, this system worked well. It provided a consistent way to identify the essentials and note major variations.

Why a New System Was Needed

Pump design is not static. Over time, new materials, internal construction changes, and application-specific features become available. Many of these options matter deeply to performance, chemical compatibility, safety requirements, and long-term reliability.

Today, there are more construction and material options than ever before. Some are less obvious, and some are internal to the pump. They may not be visible without disassembly, yet they can make the difference between a pump that performs correctly and one that fails prematurely or does not meet site requirements.

Versamatic determined that it was important to create a new nomenclature system that explicitly calls out these options and builds a higher level of detail into the pump model number.

The goal was simple: make it easier for users to identify what they are getting.

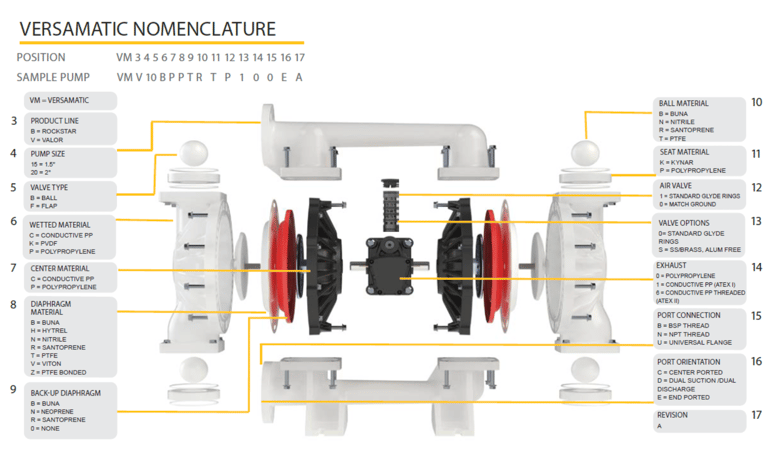

Introducing Versamatic’s New Nomenclature System

Versamatic’s updated nomenclature began with the Valor 1” poly pump. This model has a significantly different design from the E-Series, and it was a natural starting point for a more detailed system.

The updated nomenclature was also adapted to the Rockstar models, which are Versamatic’s 2” poly flap pumps. These models now include stainless flaps and seats, another example of an option that is important to call out clearly.

As future models are released, they will adopt the new nomenclature as well.

What the New Nomenclature Communicates

The most noticeable difference in the updated system is that it identifies the product line and valve type up front. That provides immediate context for the model number before you even look at the rest of the characters.

From there, the nomenclature explicitly identifies additional configuration options. These are not minor details. They can be vital to performance, compatibility, safety compliance, and the pump’s ability to meet a specific application requirement.

Versamatic’s new nomenclature can identify options such as:

- Back-up diaphragm material

- Air valve construction

- Lithium compatibility

- Aluminum-free construction

- ATEX I or ATEX II level

- Port orientation

- Future additions as new designs and options are introduced

This approach makes the model number more informative without requiring a separate decoding process for every build. It also reduces the chance that important internal features are overlooked when comparing models.

What This Means for Engineers, Distributors, and End Users

A more descriptive nomenclature system benefits everyone involved in the pump lifecycle.

For engineers and specifiers, it provides more confidence during pump selection. Instead of relying on memory, shorthand names, or incomplete notes, the model number itself communicates key build details.

For distributors and sales teams, it reduces quoting errors and helps ensure that the pump being priced is the pump the customer actually needs. It also helps when customers request replacements for existing pumps, since the nomenclature can identify options that might otherwise require manual verification.

For maintenance teams, it supports faster identification when ordering parts or confirming compatibility. When a model number includes more of the pump’s internal configuration, it becomes easier to match the correct pump to the correct service parts and application requirements.

And for facilities, the overall benefit is fewer mismatches, fewer delays, and fewer surprises.

A Model Number That Keeps Pace With Modern Pump Design

Nomenclature exists to create universal and precise product identification. For years, Versamatic’s E-Series nomenclature served that purpose by identifying basic construction and major components, with additional options added as suffixes.

As pump designs evolved, we recognized the need for a model numbering system that reflects modern construction and a wider range of material and configuration options, including options that are internal to the pump.

The updated nomenclature brings that level of detail directly into the model number. It identifies the product line and valve type up front and calls out critical options like back-up diaphragm material, air valve construction, lithium compatibility, aluminum-free construction, ATEX level, and port orientation.

As future Versamatic models are released, they will adopt this new nomenclature system, creating a more consistent and detailed way to specify pumps across the product line.

.png?width=272&height=66&name=headLogo%20(1).png)

.png?width=300&height=71&name=Versamatic_white-logo%20(1).png)