AODD pumps are known across many industries for their versatility, reliability and ease of maintenance. AODD pumps thrive in the harshest environments, safely and effortlessly carrying a wide range of fluids to keep processes working at the highest level.

However, AODD pumps may fail if the model or material selected was not designed to handle a highly corrosive chemical. In addition to creating a hazardous environment for workers, spills cause unplanned downtime and lost revenue due to leaked product and pump damage. Here’s what to know when choosing an AODD pump to avoid pump failure.

What to Know Before Buying an AODD Pump

The beauty of an AODD pump is in its simple technology. Just a few working parts ensure flawless pumping. Those working parts, however, must be compatible with your application.

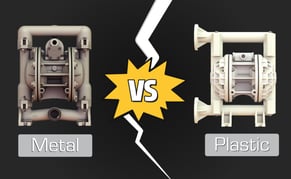

Buyers, plant managers and maintenance personnel need to consider the right material for their pump. Fortunately, there are only two main categories of pump materials: metal and plastic. It sounds like a simple choice. But, if you make the wrong choice, the pump can prematurely fail, costing you time and money.

Learning more about when to use metal pumps versus when to use plastic pumps will help you make the best decision for your application.

When to Use Metal AODD Pumps

Metal AODD pumps—which are primarily made of aluminum, cast iron, stainless steel or Alloy C and available in bolted or clamped construction—give exceptional performance in applications where higher pressures are a concern, solids/slurries handling is needed, and potentially hazardous environments may be encountered that require the pumps to be grounded.

Metal pumps are chosen because:

- They can be grounded for use in potentially explosive atmospheres (Safety/ATEX/UL Listed)

- They deal with abrasion well when fitted correctly

- They are rugged when used in portable applications like mine dewatering

- They can cost less (cast iron or aluminum) in larger sizes as compared to plastic pumps

- They are available in clamped construction for quick teardown like in hygienic applications

- Stainless steel is a good choice for food and personal care applications over plastic, which is not complementary with FDA requirements

Metal AODD Pump Applications

The durability of metal pumps is imperative for applications requiring solids and slurries handling in hazardous environments, including those containing chemicals, oil and gas. Metal AODD pumps can be used in adhesive dispensing, lubrication and original equipment manufacturing.

Benefits of Metal AODD Pumps

- Robust castings reduce damage in mobile pump applications like mine dewatering.

- Castings are abrasion-resistant when pumping abrasive materials such as ceramics.

- Aluminum and cast iron provide lower cost-effective material options.

- Most can be grounded and are ATEX compliant for safety in potentially explosive environments. Clamped construction units are designed for rapid disassemble for quick cleaning and maintenance.

- Ideal for outdoor installations because they deal with a wide range of temperatures and are not affected by UV radiation for sunlight.

- Durable and long-lasting construction with solids handling up to 0.50” (12.7mm)

High-Pressure Pumps

High-pressure pumps use two air chambers to create additional pressure. These pumps are constructed of metal so they can handle the higher pressure. These pumps are ideal in specialty applications where pressure is paramount and flow rate is critical, including filter press feeds, mine dewatering and slurry transfer.

High-Pressure Pumps Stats

- Available in sizes ranging from 1” (25mm) through 2” (51mm)

- Discharge pressure: up to 232 psi (16 bar)

- Max flow rates: as high as 90 gpm (341 lpm)

- Available in stainless steel or aluminum construction

When to Use Plastic AODD Pumps

Plastic AODD pumps offer superior chemical resistance and rugged, leak-free construction. In a world with a staggering number of chemicals in use (the U.S. Environmental Protection Agency estimates about 85,000), plastic AODD pumps can handle even the most aggressive fluids. They tend to resist corrosion, can withstand corrosive atmospheres and are lighter than metal pumps, making them easily portable. Depending on the size, plastic AODD pumps can cost less than metal units.

Common plastic AODD pump materials include Polypropylene, PVDF and Conductive Polypropylene (Conductive ATEX). Their applications are endless and include:

- Chemicals and petrochemicals

- Acids and caustics transfer/injection/dosing

- Water treatment and wastewater (filter press feed)

- Automotive service (oil and windshield solvent)

- Inks and adhesives

- OEM applications (car wash, coolant filtration, concrete additives and many others)

Plastic AODD pumps can be used outdoors but they tend to work best in controlled environments. They can be damaged if the fluid within the pump is allowed to freeze when exposed to cold temperatures. Plastic AODD pumps and components are not UV-stabilized, meaning ultraviolet radiation can negatively affect material properties. Do not expose plastic pumps to UV light for extended periods of time.

Plastic AODD Pumps Stats

- Available in sizes ranging from ¼” (6mm) through 3” (76mm)

- Max flow rate: 280 gpm (1,060 lpm)

- Max wet suction lift: 32’ (9.8 m) Max dry suction lift: 16’ (4.9 m) dry

- Max displacement per stroke: 1.0 gallons (3.78 liters)

Benefits of Plastic AODD Pumps

- Bolted construction for leak-free operation

- Lightweight construction

- Highly chemical resistant

- Wide range of sizes and applications

- Diverse material offering

- Submersible and portable

- On/off reliability

- Conductive pumps that can be grounded are available (ATEX compliant)

Premium Pumping Solutions

Now that you know more about when to choose metal AODD pumps versus plastic AODD pumps, you may have figured out the solution to the problem faced by the manufacturer of the highly corrosive chemical.

If you guessed that the pump construction materials weren’t compatible with the fluid being pumped, you’re correct. That situation proves the importance of matching the pump to the application.

Most AODD pump manufacturers offer pumps for a wide variety of applications. Reputable companies will provide a chemical compatibility chart to ensure your pump is application-appropriate.

Trusted for almost 40 years by global brands you know and use daily, Versamatic manufactures AODD pumps for a wide range of industries and applications. Versamatic’s full line of bolted metal, bolted plastic and clamped metal AODD pumps are offered in a variety of sizes and flow rates.

With outstanding durability and reliability, Versamatic pumps operate in some of the most demanding conditions in the world. All Versamatic products, including a comprehensive line of accessories for metal and plastic AODD pumps, are backed by decades of engineering expertise and an industry-leading after-sales support team to keep your pumps working at the highest level possible.

.png?width=272&height=66&name=headLogo%20(1).png)

.png?width=300&height=71&name=Versamatic_white-logo%20(1).png)