If you’re a plant maintenance manager, you understand the importance of keeping all systems and machinery running smoothly, and, in turn, production stoppage as low as possible. Production disruptions lead to lost revenue.

If you’re a plant maintenance manager, you understand the importance of keeping all systems and machinery running smoothly, and, in turn, production stoppage as low as possible. Production disruptions lead to lost revenue.

Fortunately, one of the most common pieces of equipment in plants—the air-operated double-diaphragm (AODD) pump—is designed to make maintenance simple and cost-effective. Still, an experienced plant maintenance manager will look for ways to optimize AODD pump performance to keep downtime to a minimum while maximizing efficiency.

While AODD pumps are known for reliability and versatility, there are easy ways to make them perform even better. In this blog, we’ll discuss a few AODD pump accessories and how each accessory contributes to long-term pump performance.

Diaphragm Pump Parts and Accessories

Air Filter/Regulators

One way to achieve long-term AODD pump performance is to consider your compressed air supply. Air filter/regulators play a crucial role in the performance of AODD pumps, as they prevent wet, dirty and often unregulated air from entering the pump. The combination of dirty, unregulated air can damage seals and O-rings, shortening the life of your AODD pumps.

When air is drawn into the compressor, it contains moisture that can freeze when it expands inside the pump (this is partially due to the Joule-Thomson effect). The resulting ice can cause the pump to slow, or worst-case, stall. Air filter/regulators protect the air valve of the pump by removing solids and liquid contaminants from the air lines while providing additional precise pump control.

Why Air Filter/Regulators Are Important

Air filter/regulators are essential in ensuring clean, dry air is powering the pump. Clean, dry air is critical because it:

- Helps keep tight tolerances clean and functioning correctly

- Helps avoid ice from developing in the muffler and center section

Additionally, an air filter/regulator can help you start the pump in a gradual “soft” manner, which creates less stress on the pump’s components, such as diaphragms, diaphragm plates and the main diaphragm's shaft.

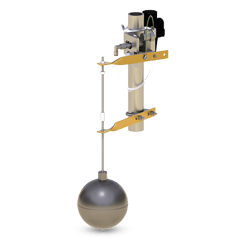

Liquid Level Controllers

A liquid level controller is another AODD pump accessory that can enhance pump performance by automatically opening and closing the pump’s air supply. Most useful in sumps, dewatering, fluid transfer and tank-filling applications, liquid level controllers are used to automatically monitor the level of liquid and ensure that the liquid is maintained at the desired level.

Liquid level controllers operate entirely by mechanical and pneumatic means, requiring no electricity. A pneumatic float switch turns the air to the pump on and off as the liquid level rises and falls. Using liquid level controllers can save you money on energy while improving diaphragm life. Most importantly, controlling air pressure can prevent premature failures, which could lead to lost product, costly cleanups and unplanned downtime.

Why Liquid Level Controllers Are Important

Completely air-driven (i.e., pneumatic) and ATEX-approved for simple, safe pump control, liquid level controllers protect AODD pumps from inefficient dry running conditions. Liquid level controls are the ideal solution for intermittent pumping applications.

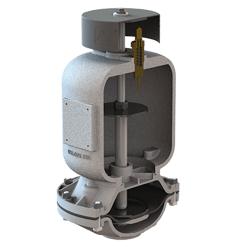

Surge Suppressors

Surge suppressors provide virtually pulse-free discharge flow for steadier pressure with less system vibration and noise.

All AODD pumps create pulsations of fluid as they operate. This is due to the column of fluid traveling with each stroke of the pump. A surge suppressor uses a single flexible diaphragm to separate a liquid chamber from a compressed air chamber. As the fluid pulse enters the surge suppressor’s liquid chamber, it displaces the diaphragm upward into the compressed air chamber. The displacement of the diaphragm absorbs the surge, fills the pressure void and effectively dampens the fluid pulsation.

Why Surge Suppressors Are Important

Surge suppressors give you a more smooth, laminar flow without the pressure variation. Consistent pressure and flow downstream will help protect instrumentation like flow meters, helping them read more accurately.

Because monitoring pump efficiency is critical in a production facility, you want to make sure you’re protecting those tools. Surge suppressors protect downstream equipment from damage caused by pressure spikes. If you use a surge suppressor or inlet stabilizer on the suction side of the pump, it will make the flow into the pump more consistent and smooth, helping to control water hammer, extending your diaphragm life.

Improve Pump Performance and Extend the Life of Your Pumps

Versamatic offers genuine AODD pump parts and accessories that enhance AODD pump performance and longevity.

Partner with us to learn how to apply Versamatic genuine AODD pump accessories to your system to keep it running smoothly and achieve optimal performance. If you have questions, feel free to contact us or a local distributor for a quality, easy-to-use pumping solution.

.png?width=272&height=66&name=headLogo%20(1).png)

.png?width=300&height=71&name=Versamatic_white-logo%20(1).png)