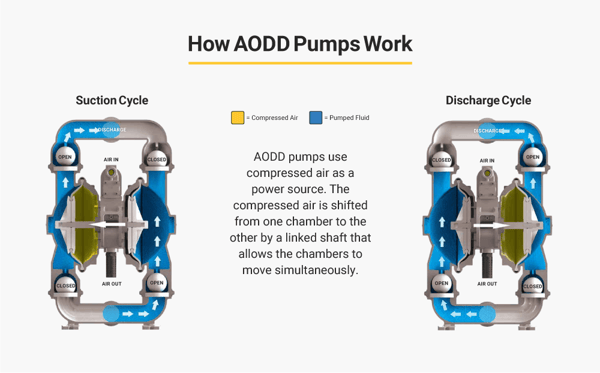

The biggest lifetime cost of a pump is powering it. Air-operated double-diaphragm (AODD) pumps, like their name suggests, run off compressed air to power the repeated back-and-forth motion of two flexible diaphragms mounted on to a common connecting rod.

The biggest lifetime cost of a pump is powering it. Air-operated double-diaphragm (AODD) pumps, like their name suggests, run off compressed air to power the repeated back-and-forth motion of two flexible diaphragms mounted on to a common connecting rod.

This continuous motion forces liquid out of one chamber for discharge while the other chamber fills with liquid on the suction stroke. Each full extension of a diaphragm is called a press stroke, and the speed at which the strokes operate impacts how much compressed air flow in CFM (cubic feet per minute) the AODD pump consumes.

Understanding Compressed Air and How it Powers AODD Pumps

While AODD pump manufacturers continue to push the efficiency envelope, standard diaphragm pumps require a significant air pressure (PSI) and volume (SCFM) to run optimally. Most AODD pumps can operate at any air pressure, typically up to a maximum of 8.6 bar or 125 PSI. However, if the air supply is obstructed, the pump will lose its effectiveness. Supplying enough air to power AODD pumps often requires expensive air compressors.

You need an air compressor that can keep up with the air your pump is consuming, which is measured in CFM, also referred to as SCFM (standard cubic feet per minute). CFM is a measure of volume of compressed air your compressor is capable of generating and an important value to know when purchasing a compressor. Every AODD pump requires a certain amount of CFM to deliver the required GPM (gallons per minute). If you invest in an efficient diaphragm pump, the energy savings will continue to add up.

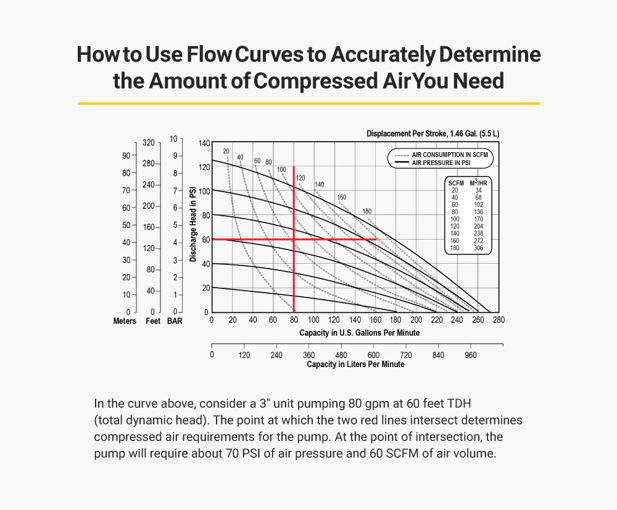

In order to understand if your current air compressor is sufficient for your needs, you’ll want to focus on the flow curve of the pump, which can be found in the service and operating manual and pump data sheet.

Understanding Diaphragm Pump Curves

When focusing on the flow curve of the diaphragm pump, look at the following: head pressure, capacity in GPM and LPM (liters per minute), air pressure in PSI, and air consumption in SCFM.

In the pump flow curve below, the horizontal red line is on 60 PSI (4.1 bar) head pressure while the vertical red line is on 80 gpm (303 lpm). To hit the duty point where the lines cross, it would require about 70 PSI of air pressure and 60 SCFM of air volume. Both air pressure and volume are equally important.

AODD pumps provide a wide range of flows without costly, sophisticated controls. Standard duty pumps operate at a 1:1 ratio, with pneumatic pressures up to 125 PSI (8.6 bar).

Other High-Pressure AODD pumps, such as a 2:1 high-pressure unit, can produce pressures up to 240 PSI (16.5 bar) when operating at 125 PSI (8.6 bar). High-pressure units are occasionally used in applications requiring greater force depending upon the need (e.g., injecting into a pressurized line, viscous fluids, or pumping further distances).

Know Your Diaphragm Pump’s Operating Point

When it comes to powering pumps, energy saved equals dollars saved. AODD pump up-sizing is one strategy to reduce AODD pump energy consumption. When you increase the size of the pump for the same desired flow, it increases the pump’s efficiency—ensuring the maximum volume of liquid is pumped per amount of compressed air consumed.

In other words, if a pump is running to the far right hand of the pump performance curve (i.e., the pump is running flat out) to produce the desired flow rate, going up one pump size can allow you to shift the performance point to the left on the curve. This means the pump will cycle slower, reducing energy consumption and extending pump longevity while getting the same desired output.

Displacement per stroke is also important to note, as there’s a direct correlation between pump longevity and efficiency. In many cases, choosing a pump with a greater displacement per stroke will reduce wear on the unit.

Displacement per stroke is also important to note, as there’s a direct correlation between pump longevity and efficiency. In many cases, choosing a pump with a greater displacement per stroke will reduce wear on the unit.

Using a larger unit can also reduce wear when pumping abrasive liquids, such as ceramic slip. By upsizing the AODD pump and running it more slowly, you reduce fluid velocity, which, in turn, reduces abrasive wear.

|

Remember: Before fluid begins to flow through your pump, there is something you can do during installation that will make it even more efficient: make sure the fluid inlet and outlet piping/fittings are at least as large as the pump’s connection size. This means if you are installing a 2" pump, it should be connected to a 2" or larger piping. If the piping is smaller than the pump size, fluid suction will be restricted and negatively affect pump flow, efficiency and diaphragm life. This step is crucial for long pump life and the most effective operation of the pump. |

Get the Most Out of Your AODD Pump

Perhaps nothing affects the pump’s longevity more than air quality. Though AODD pumps are designed to deal with poor air quality, cleaner is better.

Clean, dry air helps to reduce wear on dynamic valve and main shaft seals. External contaminants like lubrication from the compressor can attack or swell seals and, in some cases, the pump’s diaphragms.

Using a filter/regulator will help to reduce contaminants. A low-cost insurance option for your pump, air filter/regulators offer protection for diaphragm pumps powered by compressed air by controlling the incoming volume and pressure.

Air filter/regulators are also essential in ensuring clean, dry air is powering the pump. With both O-ring seals on the pilot valve assembly and main air valve, it’s important to keep the compressed air dry and debris-free.

Choose an AODD Pump Manufacturer You Can Rely On

Since 1983, Versamatic has been a market-leading AODD pump manufacturer. No matter your industry, you can count on the consistency, reliability, and trouble-free operation of our pumps.

Our tools and resources provide support options—from initial pump selection to troubleshooting and maintenance. For more information, please reach out to one of our seasoned application engineers for:

- Application assistance

- Pump selection

- Competitive information

Our application engineering team is dedicated to delivering exceptional engineering and technical assistance. This team works with our customers to understand their unique specifications, provide guidance, and develop ideal pump solutions.

DOWNLOAD THE FULL UNDERSTANDING COMPRESSED AIR AND AODD PUMPS INFOGRAPHIC.

Find these tips useful? Share which tip helped you the most in the comments below.

.png?width=272&height=66&name=headLogo%20(1).png)

.png?width=300&height=71&name=Versamatic_white-logo%20(1).png)