Leaders from many industries choose air-operated double-diaphragm (AODD) pumps for the safe and effective handling of almost any viscous fluid.

Leaders from many industries choose air-operated double-diaphragm (AODD) pumps for the safe and effective handling of almost any viscous fluid.

Performing in the most challenging applications, AODD pumps deliver unique benefits unrivaled by other pump technologies.

Understanding the following AODD pump specifications will help in determining a safe and reliable pump solution for your application: chemical resistance, required flow rate and air pressure availability.

By knowing the answer to the following three questions, the Versamatic team can help determine the right pump for your application.

1. What Are You Pumping?

The chemical resistance of a pump is essential for both safe and reliable operation. In order to recommend the correct pump, we need to know what you’re moving.

A simple MSDS sheet will give us all the information necessary, allowing us to compare those chemicals with our chemical resistance guide. The chemical resistance pertains to castings, elastomers and even center sections. Keep in mind when a diaphragm fails, the product will make its way into the center section of the pump.

2. How Much Flow?

Does your system require a specific flow rate to work properly? The desired flow rate in gallons per minute (gpm) or liters per minute (lpm) is an important factor to consider when specifying an AODD pump.

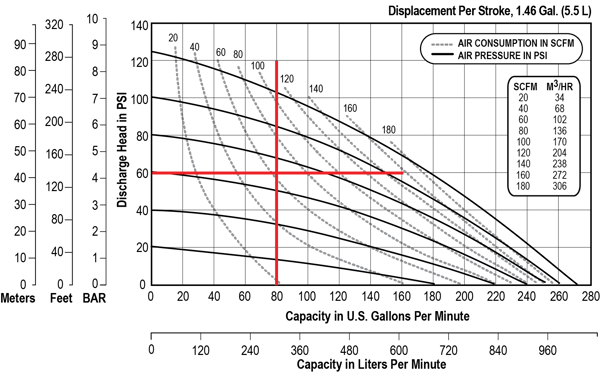

AODD pumps can perform anywhere in the envelope of 0 to 280 gpm (1,060 lpm). This is achieved with a simple adjustment of the air pressure or discharge head, giving AODD pumps an advantage over other pump technologies where it may be difficult or impossible to have that much control over the flow rate.

If you desire a higher flow rate, you’ll need a larger pump with larger port sizes. The higher the flow rate, the faster your job gets done. This ensures deadlines are met and allows increased production. In order to achieve maximum AODD pump efficiency, it’s important to determine the flow rate.

3. Do You Have Compressed Air?

Most commonly, AODD pumps, like their name suggests, run off compressed air. There are certain applications that require the pumps to be powered by nitrogen or natural gas.

Air filters/regulators play a crucial role in the performance of AODD pumps by preventing wet and contaminated air from entering the pump. When air is compressed and its temperature drops below the dew point, water can collect. While AODD pumps can handle some water, it is important that the majority is removed. This will help prevent icing and increase the life of internal components.

Air filters/regulators protect the air valve of the pump by removing solids and liquid contaminants from the air lines while providing additional precise pump control.

While AODD manufacturers continue to push the efficiency envelope, standard diaphragm pumps require significant air pressure and volume to run optimally. In order to understand if your current air compressor is sufficient, you’ll want to focus on the flow curve of the pump, which can be found in the Service and Operating Manual and pump data sheet.

In the curve below, the horizontal red line is on 60 PSI (4.1 bar) head pressure while the vertical red line is on 80 gpm (303 lpm). In order to hit the duty point where the lines cross, it would require about 70 PSI of air pressure and 60 SCFM (standard cubic feet per minute) of air volume. Both air pressure and volume are equally important.

Selecting an AODD Pump

AODD pumps can handle a wide range of chemicals, flow rates and viscosities, and can perform well in a broad array of industries.

The more you know about AODD pump specifications, the easier it will be to find the best pump for your application. Versamatic makes pumping easy with its complete line of bolted metal, bolted plastic and clamped metal AODD pumps.

If you have questions about any pumping solutions or AODD pump specifications, feel free to contact us or find a local distributor.

.png?width=272&height=66&name=headLogo%20(1).png)

.png?width=300&height=71&name=Versamatic_white-logo%20(1).png)