Plant personnel choose air-operated double-diaphragm (AODD) pumps to transfer fluids in countless markets, including cannabidiol (CBD), chemical, food and beverage, oil and gas, and many other industries. In addition to their versatility across applications, AODD pumps are a viable option for multiple pump locations within a system, including suction lift, submerged, and flooded suction positions.

Plant personnel choose air-operated double-diaphragm (AODD) pumps to transfer fluids in countless markets, including cannabidiol (CBD), chemical, food and beverage, oil and gas, and many other industries. In addition to their versatility across applications, AODD pumps are a viable option for multiple pump locations within a system, including suction lift, submerged, and flooded suction positions.

Despite their broad scope, choosing the right pump doesn’t have to be difficult. Let’s walk through the five most important factors to consider when selecting a pump for your application:

- Fluid type

- Fluid viscosity

- Flow rate

- Pressure

- Temperature

1. FLUID TYPE

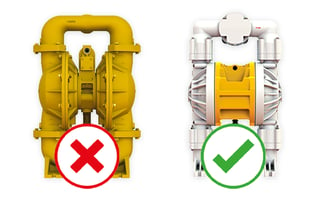

The type of fluid you’re pumping is the first thing to consider when choosing an AODD pump. More than any other factor, fluid type — whether it’s corrosive or flammable, for example — will narrow down your pump options.

It’s not as simple as choosing a metal pump for one fluid type and plastic for another. That’s why the experts at Versamatic maintain a detailed Chemical Compatibility Guide that rates various liquids used in chemical, paint, industrial, and food processing applications. Ratings range from “excellent” on one end of the spectrum down to “not advised” on the other.

In addition to a pump's material compatibility, there are other safety-related nuances to consider. For instance, flammable liquids require a groundable pump, and fluids in food and beverage applications may require pumps that are compliant with Food & Drug Administration standards.

2. FLUID VISCOSITY

How viscous your fluids are is the next factor to consider when choosing an AODD pump. AODD pumps are known for being gentle on the fluids they’re pumping, unlike some other types of pumps. Their sealless design minimizes maintenance, while preventing shearing or degrading the products they’re pumping. Consider a pie filling that you don’t want whipped up or damaged during the pumping process. An AODD pump is a good option there.

The viscosity of the fluid combined with the size of the pump will drive the flow rate. It’s important to account for these factors to be sure your pump can help you meet your operation’s goals. The viscosity correction curve is one tool you can reference to find the correct pipe size to suit your application. When in doubt, contact the Versamatic applications engineering team. They will help you apply a viscosity correction factor to identify the proper pump size based on your pumping needs.

3. FLOW RATE

As mentioned above, there is a direct correlation between the size of the pump and the flow rate. This is important to remember when sizing the correct AODD pump for your required flow rates.

Another thing to consider when it comes to AODD pumps and flow rate is that you can easily fine-tune the flow rate by controlling pressure with a filter regulator on the air inlet of each pump. With this simple addition, you can dial the pressure higher or lower to increase or decrease flow. Other types of pumps, such as centrifugal pumps, often don’t allow you to vary the flow so easily.

4. PRESSURE

The level of pressure the pump will be exposed to is the fourth factor to consider when specifying an AODD pump.

AODD pumps have a one-to-one ratio when it comes to pump pressure. The air pressure applied to the pump is the max air pressure you will achieve at the discharge. Versamatic’s metal pumps can produce a pressure of 125 psi, while our plastic pumps can produce a pressure of 100 psi. Both figures are well within the range of air pressure available at most plants. Also worth noting: For safety and reliability, Versamatic conducts a burst pressure test on all pump components.

5. TEMPERATURE

The temperature level the pump will be exposed to is the fifth factor to consider when choosing an AODD pump. Many users spend a lot of time considering chemical compatibility and pump materials, but temperature is an equally important variable when it comes to the longevity of your pump.

Ultimately, the elastomers used for a pump’s diaphragms, valve balls, seats, and seat seals help the pump handle these temperatures. Rubbers and thermoplastics are rated for different temperatures. Fluorocarbons, for instance, can withstand temperatures up to 350 degrees Fahrenheit (177 degrees Celsius). Cold temperatures, like in the production of CBD, may be better off with Teflon.

For more information on elastomer temperature thresholds, refer to the Versamatic Materials Compatibility Guide (PDF).

Still have questions about specifying the best type of AODD pump for your application? Reach out to your local Versamatic distributor today.

.png?width=272&height=66&name=headLogo%20(1).png)

.png?width=300&height=71&name=Versamatic_white-logo%20(1).png)