If you’re looking for troubleshooting tips for Versamatic air-operated double-diaphragm (AODD) pumps, you’re in the right place. You probably already know that AODD pumps are some of the most versatile, durable pumps around. Plus, they’re typically easy to fix when you know what to look for.

We’re pleased to present the following information and resources to help you fix any AODD pump issues you may be experiencing, prevent problems from happening in the future, and optimize your system for peak performance.

Read on for our Comprehensive Guide to Troubleshooting Versamatic AODD Pumps. We recommend you bookmark this page for future reference.

This guide covers:

Pump & Material Selection Tips

Tips for Preventive Maintenance & Optimizing AODD Pump Performance

Easy AODD Pump Troubleshooting Tips

First, let’s start with a review of basic AODD pump components:

.jpg?width=780&name=Diagram_of_Optimized_AODD_Pump%20(1).jpg)

AODD pump diagram key:

A, B: diaphragms

C: Connecting rod.

1–4: ball valves and I and O the inlet and outlet ports

How it works: An AODD pump uses compressed air to power the repeated back-and-forth motion of the diaphragms, which are mounted on a connecting rod. The continuous motion forces liquid out of one chamber for discharge while the other chamber fills with liquid.

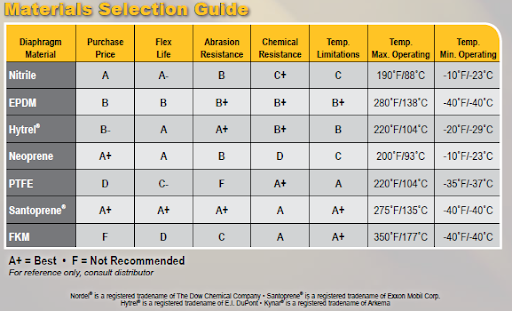

One of the most important factors is to ensure you have the right pump materials for your application. Also keep in mind whether your pump needs to meet any industry certifications, such as 3-A sanitary standards or ATEX compliance.

Metal Casting

Alloy C: Extremely chemically resistant; expensive

Aluminum: Strong and lighter weight; average chemical resistance; popular in paint, oil, gas, and mining

Cast Iron: Very strong; abrasion-resistant; heavy for mobile applications

Stainless Steel: Excellent chemical resistance; commonly used for food processing applications

Plastic Coating

Conductive Acetal: Can be used to prevent static discharge for pumping flammable liquids

Polypropylene: Strong chemical resistance for acids and caustics; lightweight; affordable,

depending on the pump size

PVDF: More chemically resistant than polypropylene; can handle most acids and caustics, even at

higher concentrations; very strong; handles abrasion better than polypropylene

Remember to always consult the pump manufacturer with any questions about material selection.

As you troubleshoot your AODD pump, performance specifications are another important thing to keep in mind. Consider flow rate, which helps determine pump size.

Flow rate, expressed in gallons per minute (gpm) or liters per minute (lpm), is the amount of fluid you can move within a given time. Knowing this will help you determine if your AODD pump isn’t working efficiently or if you need a different pump for your system.

AODD pump flow rates range from 0 to 280 gpm (1,060 lpm). To control the flow rate, simply adjust the air pressure or discharge head. If you need a higher flow rate, you’ll have to get a larger pump.

How to calculate the flow rate of an AODD pump:

Once you know the flow rate, it will help you determine the AODD pump size you need. Whenever possible, go up one size pump. Doing so will prevent your pump from running near maximum capacity, which leads to wear and tear on the pump and reduces efficiency. Going up one size allows you to run the pump at fewer strokes per minute, which will reduce air consumption and extend the life of the pump.

Set up your operation for success by installing AODD pumps properly with these suggestions.

An AODD pump leak indicates you have a problem and you need to troubleshoot it quickly before you have further damage, a major maintenance issue, or a safety concern on your hands. Luckily, many AODD pump leaks are easy to fix once you identify the problem.

Why do AODD pumps leak in the first place? Leaks usually happen at a pump’s weakest point, so they’re typically due to one of the following issues:

Identifying the leak location can help diagnose the problem in some cases.

Observing the diaphragm is often the best way to understand and fix leaks.

| Diaphragm Observation | Potential Issue | What to Do About It |

| Discoloration or cracking | Excessive heat or chemical attack | Check chemical compatibility of elastomers and/or temperature of product. |

| Bubbling around the edge | Excessive heat or chemical attack | Ensure chemical compatibility of elastomers and/or temperature of product. |

| Wear marks on one side | Excessive suction-side pressure or imploded air side | Observe gauge on suction side for increased pressure. Try to keep below 10 psi (0.7 bar) of NPSH. |

| Star pattern cracking | Dry running | Shut pump down when not in use. Potential application for liquid level controller. |

| Outer diaphragm plate imprint | Over-torquing | Follow manufacturer torque specifications. |

Remember: If you have to replace a diaphragm or another pump part, whether it’s due to a leak or any other reason, replace all the components at the same time. It makes sense to replace everything while your pump is out of service to prevent future downtime. That’s why our service kits include all the parts you need to do a complete replacement.

Suction malfunctions are another problem that can damage an AODD pump if you don’t identify and fix them quickly. There are a few ways to avoid suction malfunctions in the first place:

If you're amid a suction malfunction, those preventive measures won’t help you. First, you need to identify your problem and understand what's causing it, and then fix it. The three most common AODD pump suction problems — and their fixes — are:

If an AODD pump is operating erratically — making hissing sounds or only cycling once — you need to troubleshoot the situation ASAP. You don’t want it to lead to pump damage or downtime.

First, let’s talk about prevention. It’s always important to make sure your air inlet line size and air pressure are right for your application. Also, ensure the suction line isn’t clogged and that it’s not positioned at the bottom of the tank.

If you’ve covered those measures and you’re still dealing with erratic operation, consider the following potential problems and solutions.

If you are experiencing a clogged suction, discharge lines, or manifolds, first be sure to clear debris from the pump. Next, install a filter on the pump’s suction side to keep debris from building up again. This step will extend the lifespan of the diaphragms.

Another potential problem is lack of air or too much air supply. Make sure you’re running your AODD pumps at their ideal pressure point (between 60 and 80 psi). They can handle 125 psi, but that’s not ideal on an ongoing basis.

A third common erratic operation issue is an iced-over exhaust. If you’re in this situation, you can fix it by installing a dryer before the pump air inlet. You can also extend the pump’s exhaust to move the compressed air away from the center section.

If your AODD pump stops unexpectedly, you have a problem. Before you fix it, first determine if your problem is on the air end or wet end of your pump.

If your problem is on the air end, you’ll be focusing on the pilot valve or main air valve.

The most common source of problems on the air end is dirty air. Upon disassembly, if you see pipe sealant, weld berries, or dirt, you likely need an inline filter. If you don’t see any dirt or debris but you see process fluid, you may have a diaphragm failure or a loose diaphragm plate assembly.

Clean, inspect, and replace the components. Then you can reinstall the main air valve and pilot valve. To save time and rule out wet-end components, we recommend keeping spare air valves and pilot valves on the shelf for testing purposes. Wear components on the main air valve include O-rings and Glyd Rings or U-cup seals. You can replace these as individual components or buy them as a complete kit.

Wear components on the pilot valve include self-sealing floating pneumatic O-rings, which you can evaluate and replace if needed. Also, verify all air passages are debris-free before reinstallation.

If your problem is on the wet end, you may be experiencing diaphragm failure. If fluid is exiting the pump through the exhaust, that’s an obvious sign.

To fix it, you first need to shut down the pump, isolate it, and remove it from the system for repair. Next, look closely at the diaphragms. The following are common observations and what they could mean.

Punctures

A sharp item may have entered the pump and created a cut or hole. After removing debris, install a screen filter on the suction line to prevent future punctures.

Scratch marks

High fluid inlet pressures can create scratch marks on the air side of the diaphragm where contact is being made with the inner chamber. This occurs most often in flooded suction applications. Fix it by raising the pump so the centerline is closer to the fluid or by installing a back pressure device on the exhaust.

Stretched center hole

If you observe a stretched center hole, your outer diaphragm plate may be torqued incorrectly. You also may have high fluid inlet pressures causing the diaphragm to overstretch. Verify torque specifications in the pump’s service and operating manual.

Bubbling or deterioration

Bubbling and deterioration are signs of a chemical problem. Refer to the manufacturer’s chemical compatibility guide to verify you have the correct materials for your application.

Still need assistance troubleshooting your AODD pump? Please contact us today or check out some of our additional resources below:

As a reliable global air-diaphragm pump manufacturer, Versamatic has the AODD pumps that are the first choice for customers around the world who value reliability, quick delivery and convenience. Our dedicated team of distributors is always available to provide excellent service and advice.

800 North Main Street

Mansfield, OH 44902

© 2026 Versamatic | All rights reserved | Terms of Access | Privacy Statement | Patents | Website by SyncShow